Smart Robotic Hand Technology Powers LPTech’s Ambition to Reach KRW 10…

Author관리자

- Date of Registration 26-01-16

- Views2Count

본문

LPTech Combines German-Level Technology with Price Competitiveness, Drawing Global Interest from France, Peru, and Beyond

Robots are industrially valuable because they can perform work—and to do so, they inevitably require hands, or grippers. This is why companies across the robotics industry are racing to develop high-performance grippers.

A company that has recently drawn attention in Korea’s robot components market by developing a new-concept gripper with a proprietary structure is LPTech Co., Ltd., a gripper-focused robotics company. With just four employees, LPTech recorded KRW 2 billion (approx. USD 1.5 million) in revenue last year, earning recognition as a dark horse in the robot gripper market.

A Smart Factory Expert Sees the Future in “Robot Hands”

For years, robotics experts believed that creating a “usable robot hand” required human-like tactile sensing, leading to the adoption of high-performance sensors and even artificial intelligence (AI). The prevailing assumption was that such technologies were essential for handling objects freely and precisely.

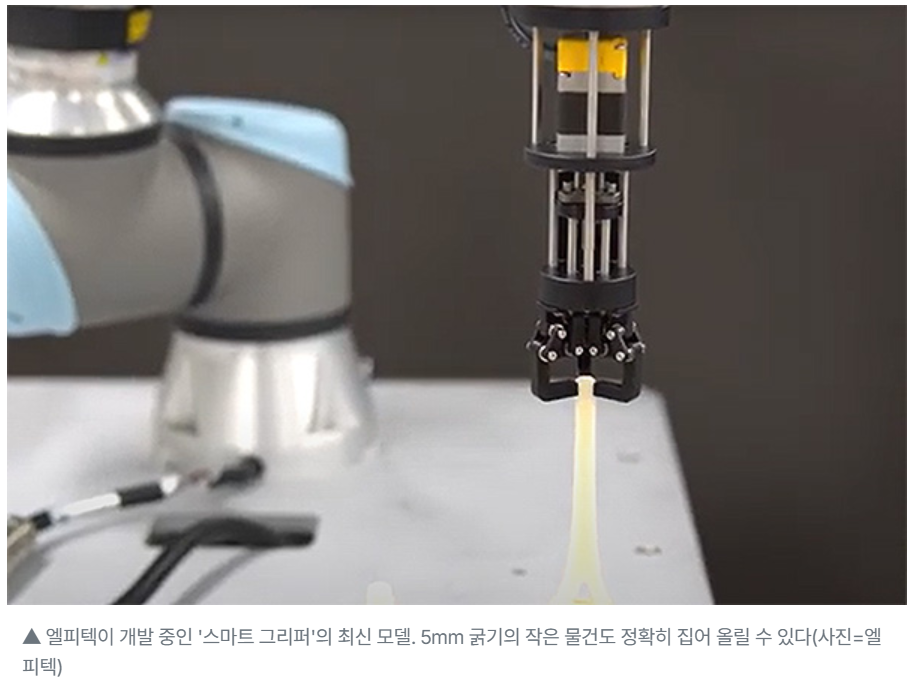

However, Park HyungSoon, CEO of LPTech, took a fundamentally different approach. By designing a unique structure using three robotic fingers, he realized precise handling without expensive sensors. With no sensors, complex AI learning processes were unnecessary. Park named this approach “Teaching-less.”

Park is a robotics expert with more than 10 years of hands-on experience in technology sales and development at multiple engineering firms, including JC International and MC Tech.

“As I focused on smart factory projects, I realized that the core of production automation ultimately lies in a precise robot hand—the gripper,” Park said.

“When building smart factories, the ability to accurately and flexibly handle objects of various shapes and sizes became absolutely critical. Existing products were either too expensive or limited to specific tasks, so I decided to build one myself.”

From the “Gochujang Gripper” to the Smart Gripper

LPTech was founded in 2021 during the COVID-19 pandemic. At the time, Park learned that a major Korean food manufacturer was developing multiple grippers to handle different types of food containers in an automated line. He believed that these could be replaced by a single universal gripper.

After a year of R&D, LPTech successfully developed a prototype called LPTG-F01, which Park nicknamed the “Gochujang Gripper,” as it was designed to handle gochujang containers in food factories.

The company later refined this design into its current flagship model, LPTG-FS03, commonly referred to as the Smart Gripper. Like its predecessor, it operates without expensive sensors and relies solely on motor control technology, but with significantly improved functionality and stability.

Achieving Both Performance and Cost Competitiveness

“High-performance robot grippers usually require pressure or contact sensors,” Park explained.

“Each sensor can cost KRW 1–2 million, so a five-finger gripper can require nearly KRW 10 million just in sensor costs.”

LPTech instead implemented advanced torque-based motor control, allowing the gripper to recognize object size and shape and apply appropriate gripping force without sensors. Combined with its proprietary three-finger structure, the gripper can handle virtually any object that fits within its gripping range.

As a result, product pricing dropped dramatically—while response speed actually improved compared to sensor-based systems, due to the absence of complex calculations. Another major advantage is that objects of varying sizes can be handled immediately without additional programming or learning, eliminating the need for vision systems or extensive pre-configuration.

From a manufacturer’s perspective, this significantly reduces both cost and implementation time, while system integrators benefit from a much simpler automation design process.

Currently, the only commercial gripper with comparable functionality is produced by Schunk, a leading German robotics components company, which reportedly generates over KRW 2 trillion in annual revenue from its gripper product line alone.

“We are confident that our technology outperforms competitors, while being far more affordable,” Park said.

“A Schunk gripper costs around KRW 10 million per unit and requires an expensive controller. LPTech’s Smart Gripper costs approximately KRW 5 million and requires no separate controller.”

Expanding into Global Markets: France, Peru, and Beyond

Backed by its technological and pricing advantages, LPTech is growing rapidly. After product evaluations by major Korean corporations in 2022, the company began official supply contracts in 2023, with additional orders coming from overseas clients, including Vietnam.

With only four employees—three of whom are dedicated to R&D—LPTech achieved KRW 2 billion in revenue in 2024, a remarkable milestone considering the company had just two employees the previous year. Revenue is expected to grow by more than 50% this year.

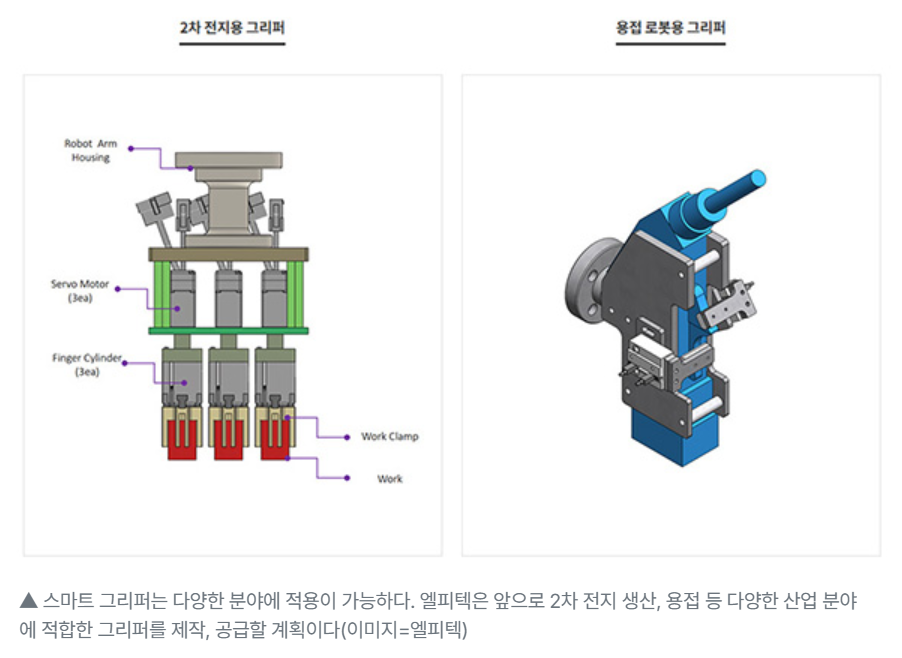

LPTech has also completed development of a new gripper for secondary battery (EV battery) production lines and is preparing for full-scale overseas expansion, targeting Indonesia, France, and Poland.

“When we speak with local companies, many are surprised by both our technology and pricing and want to sign contracts on the spot,” Park said, expressing confidence in global market expansion.

However, the company remains cautious about indiscriminate expansion, refusing small orders below KRW 500 million to protect its intellectual property and ensure minimum technology licensing value.

Unexpected Opportunities in Peru and France

LPTech’s overseas expansion began unexpectedly. During a visit to Indonesia last July, Park met a Korean entrepreneur operating in Peru. This connection led to participation in a Peruvian exhibition related to a smart city project, where LPTech’s booth attracted large crowds and strong interest.

Park plans to visit Peru later this year to advance concrete business discussions.

France has also emerged as a promising market. Park spent two months in France starting in September last year, directly assessing local conditions. He found that frequent strikes and labor shortages make robotic automation—and particularly LPTech’s Smart Gripper—an attractive solution for French manufacturers.

During this period, LPTech held positive discussions with executives from the French robotics association regarding local subsidiary establishment and investment. A representative from Bpifrance, the French public investment bank, even visited LPTech personally and requested the establishment of a subsidiary in a specific region of France.

LPTech is currently identifying a trusted local executive as it moves forward with plans to establish a French subsidiary.

Looking Ahead

In the short term, LPTech aims to surpass KRW 10 billion in revenue by aggressively targeting global markets. Long term, the company envisions becoming a KRW 100 billion “hidden champion” in the global robotics components industry. An IPO will be considered strategically as part of this growth journey.

The company is also expanding its product portfolio and is currently developing next-generation grippers capable of handling ultra-small objects under 5 mm.

“Through continuous technological innovation, we aim to strengthen the competitiveness of Korea’s manufacturing industry,” Park concluded.

“Ultimately, our goal is to become a globally recognized high-value robotics components company.”

Source : 로봇신문 (https://www.irobotnews.com/news/articleView.html?idxno=38426)